Safety Precautions: Prioritizing Your Well-being

Before commencing any testing of your tractor protection valve (TPV), prioritize safety. A moment of preparation can prevent serious injury. Choose a level, stable surface to park your tractor. Engage the parking brake firmly to prevent any unintended movement. Always wear appropriate personal protective equipment (PPE), including safety glasses to shield your eyes from potential debris and gloves to protect your hands from grease and dirt. Sturdy work boots are also recommended. Remember, safety isn't optional; it's paramount. For more information on TPV function, check out this helpful resource: Learn more about TPVs.

Tools and Equipment: What You'll Need

Testing your TPV requires minimal tools. Gather the following:

- The correct-sized wrench for your tractor's TPV connections (consult your owner's manual).

- A leak detection spray (highly recommended for precise leak identification).

Step-by-Step Testing Procedure: A Detailed Guide

This section provides a clear, step-by-step guide for testing your TPV. Follow these instructions meticulously for accurate results.

Isolating the Trailer: Carefully disconnect the air line connecting your tractor to the trailer. This isolates the trailer's air brake system, preventing interference during the TPV test.

Securing the Trailer's Air Supply: Locate and firmly close the trailer supply valve on your tractor (usually clearly marked). This prevents air from flowing back into the trailer brake system.

Engaging the Service Brakes: Fully apply the tractor's service brakes. This pressurizes the TPV, allowing you to assess its ability to hold pressure.

Listening for Leaks: The Aural Check: Carefully listen around the trailer service line connection for any hissing sounds. A hiss indicates an air leak, suggesting a potential TPV malfunction.

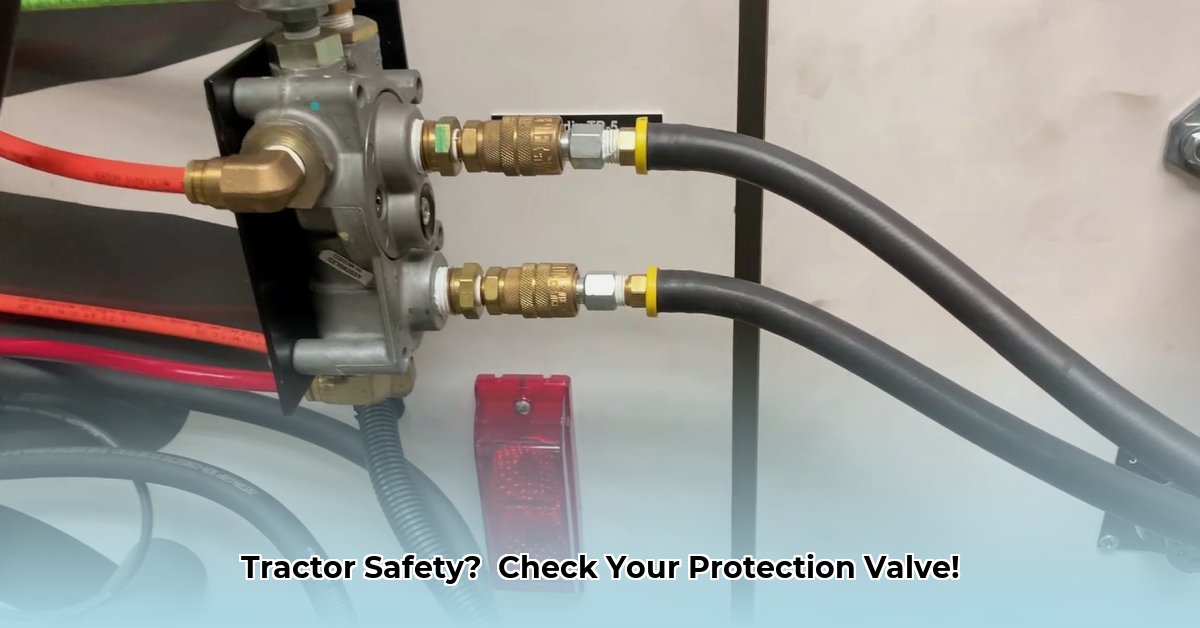

Visual Inspection (Using Leak Detection Spray): Apply leak detection spray to the TPV and all its connections. Observe carefully for any bubbling or escaping air, pinpointing the exact leak location.

Releasing the Brakes: After the aural and visual inspections, carefully release the tractor's service brakes.

Reconnecting the Trailer: Once the test is complete and the TPV's functionality is confirmed, carefully reconnect the air line to the trailer. Ensure a secure connection.

Interpreting the Results: Understanding Your Findings

The outcome of your test will clearly indicate the TPV's condition:

Leak Detected (Hissing or Bubbles): A hissing sound or bubbles from the leak detection spray signify a leak, indicating the TPV isn't sealing correctly. This poses a significant safety risk, requiring immediate professional attention. Remove the tractor from service and consult a qualified mechanic.

No Leak Detected (Silent, No Bubbles): A silent valve and absence of bubbles suggest the TPV is functioning correctly. However, remember this only assesses the TPV; other brake system components may require separate checks.

Troubleshooting: Addressing Common Issues

Even with a functioning TPV, preventative maintenance is critical.

Persistent Leaks: Recurring leaks point to a more serious problem requiring professional diagnosis and repair. Consult your tractor's manual or a mechanic. TPV replacement might be necessary.

Regular Inspections: Regularly inspect TPV connections and lines for damage, corrosion, or debris buildup. Cleaning connections prevents issues from developing.

Maintenance Recommendations: Proactive Care

Regular maintenance prevents TPV failures. Visually inspect the TPV and its connections for any signs of wear, damage, or leaks. Use leak detection spray during routine checks for a thorough assessment. Schedule professional inspections as part of your preventative maintenance program.

Regulatory Compliance: Meeting Legal Standards

Regular TPV testing is often legally mandated. Consult your local and national regulations to ensure compliance and avoid potential penalties. Prioritize safety and adhere to all relevant standards.

Conclusion: The Importance of Regular TPV Testing

Regular TPV testing is a crucial aspect of safe tractor operation. This simple procedure safeguards your safety and avoids costly repairs. Don't underestimate its importance; your diligence is an investment in safe operation and peace of mind.